Tailored Motion Control Solutions for Industry Challenges

- OMS Sales Team

- Aug 13

- 3 min read

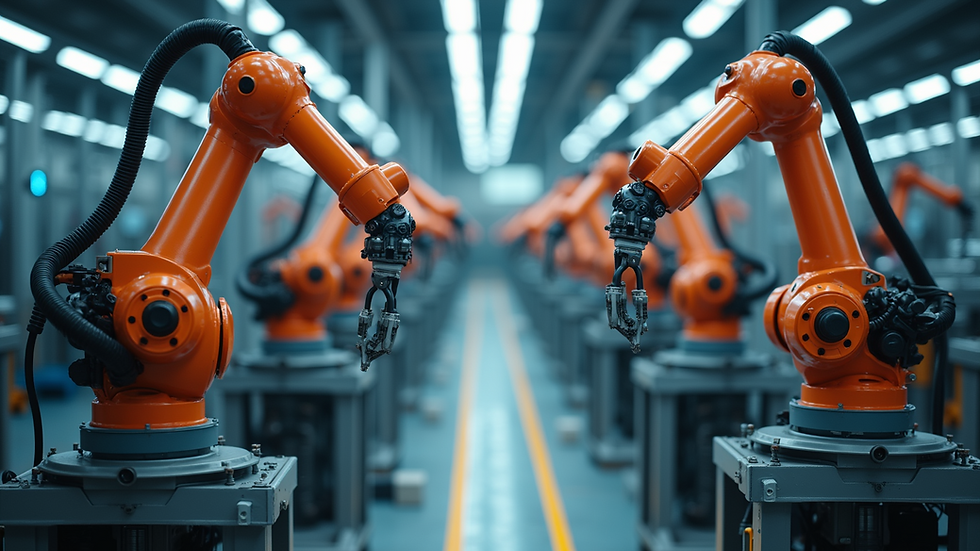

In today’s fast-paced industrial landscape, precision and adaptability are key to maintaining competitive advantage. Industries ranging from manufacturing to robotics demand highly specialized systems that can deliver exact movements with reliability and efficiency. Tailored precision motion solutions have emerged as the cornerstone for overcoming complex operational challenges, enabling businesses to optimize performance and reduce downtime.

Understanding Precision Motion Solutions

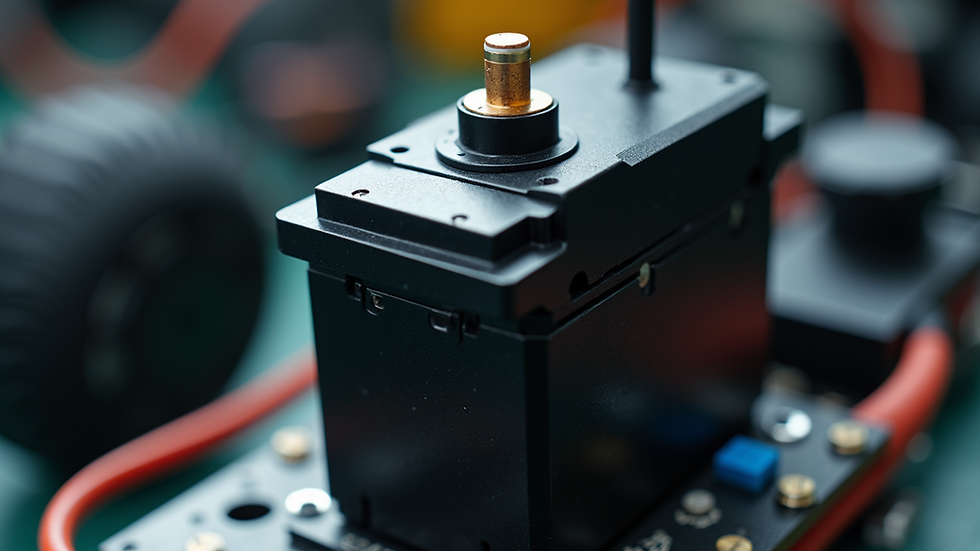

Precision motion solutions refer to engineered systems designed to control the movement of machinery and equipment with high accuracy. These solutions integrate components such as motors, drives, sensors, and controllers to achieve smooth, repeatable, and precise motion. The goal is to ensure that every movement is executed exactly as intended, minimizing errors and maximizing productivity.

For example, in semiconductor manufacturing, even the slightest deviation in motion can lead to defects in microchips. Precision motion systems ensure that robotic arms and positioning stages move with micron-level accuracy, safeguarding product quality. Similarly, in packaging industries, these solutions enable high-speed, synchronized movements that maintain packaging integrity while increasing throughput.

Key components of precision motion solutions include:

Servo motors: Provide controlled rotational or linear motion with feedback for accuracy.

Linear actuators: Convert rotary motion into linear displacement for precise positioning.

Motion controllers: Coordinate the timing and sequence of movements.

Sensors and encoders: Monitor position and speed to provide real-time feedback.

How Precision Motion Solutions Address Industry Challenges

Industries face a variety of challenges that require customized motion control strategies. These challenges include:

Complex motion profiles: Some applications require multi-axis movements with varying speeds and accelerations.

Space constraints: Equipment often needs to fit into compact spaces without sacrificing performance.

Environmental factors: Harsh conditions such as dust, moisture, or extreme temperatures demand robust solutions.

Integration with existing systems: New motion solutions must seamlessly work with legacy equipment and software.

Tailored precision motion solutions tackle these issues by offering modular and scalable designs. For instance, a food processing plant may require a compact, washdown-rated motion system that can withstand frequent cleaning cycles. A tailored solution would use stainless steel components and sealed motors to meet hygiene standards while maintaining precision.

Moreover, advanced software algorithms enable adaptive control, allowing machines to adjust motion parameters in real-time based on sensor feedback. This adaptability reduces wear and tear, extends equipment life, and improves overall efficiency.

Who Bought Motion Solutions?

Various industries have adopted tailored precision motion solutions to enhance their operations. Some notable sectors include:

Automotive manufacturing: Precision motion systems are used in assembly lines for tasks such as welding, painting, and component placement.

Medical device production: High-precision motion is critical for assembling delicate instruments and ensuring consistent quality.

Aerospace: Motion control solutions enable the precise machining and inspection of aircraft components.

Electronics: Automated pick-and-place machines rely on accurate motion to handle tiny components.

Companies investing in these solutions often report significant improvements in production speed, product quality, and operational flexibility. For example, a leading electronics manufacturer integrated a multi-axis motion control system that reduced assembly errors by 30% and increased throughput by 20%.

Practical Recommendations for Implementing Tailored Motion Solutions

When considering the adoption of tailored precision motion solutions, businesses should follow these practical steps:

Assess specific application needs: Identify the required accuracy, speed, load capacity, and environmental conditions.

Engage with experienced solution providers: Collaborate with experts who understand industry-specific challenges and can customize systems accordingly.

Plan for integration: Ensure compatibility with existing machinery, control systems, and software platforms.

Prioritize scalability: Choose modular components that allow future upgrades or expansions.

Invest in training and support: Equip your team with the knowledge to operate and maintain the new systems effectively.

By following these guidelines, companies can maximize the return on investment and minimize disruptions during implementation.

The Future of Precision Motion Solutions in Industry

The evolution of precision motion solutions is closely tied to advancements in technology such as artificial intelligence, IoT, and machine learning. These innovations enable smarter, more autonomous systems capable of predictive maintenance and self-optimization.

For example, integrating sensors with cloud-based analytics allows real-time monitoring of equipment health. This proactive approach helps prevent unexpected failures and reduces downtime. Additionally, AI-driven motion controllers can adapt to changing production requirements without manual intervention, enhancing flexibility.

As industries continue to embrace digital transformation, tailored precision motion solutions will play an increasingly vital role in driving efficiency, quality, and innovation.

Explore more about motion control solutions and how they can be customized to meet your industry’s unique challenges.

Comments